The dental market uses a wide range of adhesives and sealants for applications from protecting teeth to keeping dentures, crowns and prostheses in place.

Water-soluble medical tape for surgical solutions

Water-soluble hot-melt medical tape is uniquely designed for sustainability and reuse for surgical procedures. More and more hospitals rely on reusable surgical tape instead of disposable alternatives, and the application and washing processes must be as efficient as possible. A medical adhesive that is 100% water-soluble has been recently developed. This adhesive medical tape adheres to both skin and textile, is easy to apply and remove, and allows for maximum efficiency.

Medical tape that uses these wash-off adhesives is suitable for applications between surgical tape and the patient’s skin. The medical adhesive ensures that surgical tape stays in place and helps create and maintain a sterile, hygienic environment during surgical operations.

Why choose a water-soluble medical adhesive?

Water-soluble medical adhesive is an acrylic pressure and temperature-sensitive system which adheres well to skin and textiles. The double sided medial adhesive tape is ideal for use in medical environments. The surgical tape is also biocompatible. There are additional beneficial characteristics:

- Water and solvent free: as a medical adhesive, the water-soluble adhesive does not contain any water or solvents. It appears solid at room temperature but is liquidized when the temperature rises.

- Steam sterilization: the water-soluble adhesive is not affected by steam sterilization, although the heat does promote adhesion due to the temperature-sensitive nature of the self-adhesive material. The medical tape reaches its ultimate strength on the textile side after steam sterilization.

- Resistant to body fluids: even though the adhesive is water-soluble, it is important to emphasize that the adhesive is more specifically wash-soluble—i.e., water and body fluids do not affect the surgical tape during surgeries.

- 100% wash soluble: after surgery, reusable tape is prepared for washing. Normally, preparation includes removing medical tape and adhesive residue, but with wash-off medical adhesive this is not necessary. Medical drapes can be washed with the surgical tape, which completely dissolves during the wash.

Other uses of water-soluble adhesive tape

Even though the water-soluble adhesive is designed for use as a medical tape adhesive, its unique properties are useful in other applications, such as in the textile industry. The innovative uses of the adhesive include for instance temporary textile glue, adhesive for modeling and reusable fabrics, as well as water-soluble glue for clothing design. Contact us in case you are interested in the further possibilities of the water-soluble adhesive, or if you would like to know whether water-soluble is the solution for your adhesive needs.

How water-soluble medical tape works

Water-soluble adhesive is a common part of surgical tape systems. These are often double-sided and consist of a carrier which is coated with adhesive on both sides and a liner which can be removed prior to bonding. Medical tape is available with various dimensions and can be customized by adding a print on the carrier.

The tapes with medical wash-off adhesive are mainly applied for two reasons:

- to bond medical drapes to skin in order to keep drapes in place during surgery

- to create and maintain a sterile, hygienic operating environment

Often, medical glue is applied to surgical tape before being supplied to hospitals or clinics. Drapes must be steam-sterilized before use in operation theaters in order to guarantee sterility and allow medical tape adhesive to reach its ultimate strength. Once sterilized, drapes are placed on the patient and medical drape tape liners are removed so that medical tape adheres to the skin.

After surgery, drapes can be washed without removing the medical tape. The 100% water-soluble adhesive dissolves during the washing process without leaving a trace in the drapes or the washing machine. In addition, the carrier dissolves when washed.

Relevant medical tape adhesive certification

The medical industry is strictly regulated by standards and tests by various parties, and it is crucial to be aware of these regulations when looking for medical tape. For example, CE marking, according to the EU Medical Device Regulation (MDR) 2017/745, is important to look at. Furthermore, one should opt for surgical tape from manufacturers that have been certified according to ISO 13485, which demonstrates the organization´s ability to produce approved medical devices and related products and services.

Additionally, when looking at the medical adhesive, several international standards are applicable. The adhesive should be tested for cytotoxicity, skin irritation, and skin sensitization, among other things, which are included in ISO 10993-5 and ISO 10993-10.

Interested in water-soluble adhesive or tape?

As wash solvability is a rather new characteristic among adhesives, make sure to have your surgical tape supplied by a reliable source. If you are looking for water-soluble adhesive or water-soluble medical tape, contact us. We are happy to connect you with an adhesive specialist with a proven track record of water-soluble bonds.

Sterile surgical systems: medical adhesive film

Operation theaters require a high standard of sterility at all times, to ensure protection of skin during incisions. Surgical glue standards are no different. Medical adhesive film can be of great help when making and gluing incisions, as it maintains a sterile environment during operations as well as guaranteeing maximum efficiency of surgical procedures.

Medical adhesive film systems vary per manufacturer, however, here we will focus on sterile, transparent incision film which is applicable to disposable surgical drapes and skin prior to sterilization. The medical transparent adhesive film increases surgical glue sterility while at the same time protecting the skin around the operated area during, for instance, a c-section or an abdominal surgery.

Medical transparent adhesive film: components and uses

Medical adhesive film for drapes and skin often consist of a transparent polyurethane layer, a special UV adhesive and a release liner as well as a finger lift. An additional polyethylene layer is possible in order to provide support when in the operation theatre.

Incision films are the most common in operations such as cesarean sections and abdominal surgery. They are applied for two main reasons:

- To maintain a surgical glue’s sterile environment during operations.

- To protect the skin around operation areas.

Sterile incision films come in all shapes and sizes and are available with custom dimensions, special adhesive systems, customized perforation and print depending on what is needed. Contact us to find the adhesive film that meets your needs.

Sterile surgical systems prepared by adhesive film manufacturers

One of the most important components of sterile incision films is the adhesive as the characteristics of the film greatly depend upon the properties of the adhesive.

Typically, sterile surgical systems make use of pressure sensitive adhesives which implies that bonds are formed as pressure is applied. This is no different for medical adhesive film. However, the adhesive in incision films is often also temperature sensitive meaning that the body heat of the patient enhances the bonding process. Also UV adhesives are common in medical films as they are easy to apply and guarantee an efficient film production process.

In sterile incision film systems one side is commonly coated with a UV pressure sensitive adhesive. Due to the pressure and temperature sensitive nature of the medical adhesive it adheres well and easily to surgical drapes and skin.

Benefits of medical adhesive film provided by the adhesive

The purpose of the adhesive is not limited to simply sticking things together while in the operation theater. It also provides the medical transparent adhesive film with beneficial properties. Some properties of the film are increased or supported by the adhesive. The benefits the adhesive contributes to include the following.

- Breathability: as surgical glue comes in contact with skin, breathability is crucial to avoid any post-surgery skin irritation. Depending on the adhesive and the design of the medical adhesive film (perforated or non-perforated) different levels of breathability can be reached. UV curing adhesives allow for breathability of the adhesive.

- Resistance to fluids: the adhesive used in incision films is resistant to water and body fluids as well as alcohol and detergents. This prevents the fluids from affecting the skin under the film and so maintains sterile environment during surgical operations.

- Disinfection: resistance to alcohol and detergents makes it possible to disinfect the film after it has been placed on the drapes and skin to minimize the presence of bacteria and other microorganisms.

- Maximum performance: during operation theater surgical procedures, the medical adhesive film allows for maximum performance as sterilization can be done on the spot and the clean environment is maintained throughout the operation.

In addition to the benefits the film receives from the adhesive, the adhesive also has advantages regarding the manufacturing process. UV curing adhesives are usually environmentally friendly and allow for efficient, low waste medical adhesive film production. Even though the UV pressure sensitive adhesives are most common in incision films, they are suitable for many more innovative purposes. Contact us to find out whether UV pressure sensitive adhesive is what your product, project or process needs!

Medical adhesive film application procedures

Sterile incision glue can be applied to the drapes prior to being supplied to the end user or at the operation theater setting right before the surgery. In both cases, before placing the film on the patient’s skin, the skin is disinfected by iodine or another disinfectant. The skin is let dry, as the adhesive forms better bonds when applied to a dry surface. Letting the disinfectant dry also increases the level of sterilization. Once the film is in its place, and the liner is removed, it gets sterilized to avoid any microorganisms interfering with the operation.

During the operation incisions are made through the transparent film. Afterwards, the film is removed, appropriately disposed and the wound can be stiched. Note that it is not possible to stitch through the film.

Sterile incision film system certifications

As the medical industry is strictly regulated by standards and tests by various parties, it is crucial to be aware of some when looking for a medical adhesive film. Next to paramount CE marking according to the EU Medical Device Regulation (MDR) 2017/745, it is important to look for film suppliers who have obtained the ISO 13485 certificate which proves their ability to produce approved medical devices and related products and services.

Additionally, when looking at the adhesive several international standards are applicable. The adhesive should be tested for instance for cytotoxicity, skin irritation and skin sensitization. These are included in ISO 10993-5 and ISO 10993-10.

Looking for medical adhesive film – or just the surgical glue?

As medical adhesive film for surgical operations come in a wide variety of forms, one should always opt for the most suitable product. In case you are looking for a reliable medical adhesive manufacturer with a proven track record of surgical glue systems approved for medical use, do not hesitate to contact us. Our experts are determined to connect your enquiry with the most suitable medical adhesive film manufacturer who can provide you with custom dimensions, perforation, special bonding systems and print on the film.

Hygiene products benefit from nonwoven construction adhesive systems

The largest, and fastest growing, user of nonwoven materials is the hygiene products industry, which means that it also consumes the most nonwoven construction adhesive systems. The materials and adhesives are common in products like baby diapers, adult incontinence products, children’s swim and training pants as well as feminine hygiene pads and shields. The purpose of the nonwoven hygiene construction adhesive solutions is to bond together the different layers of the nonwoven materials.

Most of the hygiene products are subject to mass production at low cost. The high production and reduced costs are made possible by hygiene adhesive solutions. Even though each product uses only a small amount of adhesive (4%, 1 to 1.5 g in an average baby diaper), the hygiene construction adhesive systems really make a difference. Not only do they efficiently bond components together but also guarantee fit, retention, breathability, absorption and comfortable feel.

Nonwoven hygiene construction adhesive requirements

The non woven adhesive market is currently confronted by several requirements that derive from several sources. Consumer and brand needs as well as different local and international rules and regulations affect the formulations of adhesives for nonwoven materials. Generally, one should be looking for a nonwoven construction adhesive that meets the following requirements.

Fast and easy to apply

Depending on the required efficiency of the production, the hygiene adhesive solutions must be easy to apply and fast curing in order to keep up with the high paced production. For example an average diaper manufacturer makes between 800 and 1000 baby diapers per minute.

Maintaining product reliability and quality

As the nonwoven construction adhesive bonds together the layers of the hygiene products, it is crucial that the quality of the products does not suffer. Better yet, one should opt for adhesives for nonwoven materials that promote product reliability.

Increased sustainability

One of the most important criteria for hygiene construction adhesives is that it results in products that are environmentally friendly enough to satisfy the consumers´and brand´s needs as well as meeting local and international regulations. The hygiene products that use non woven materials are disposable and therefore, not always considered the most sustainable. However, the nonwoven adhesive market is striving towards hygiene adhesive solutions that result in less waste, can be recycled or even composted. One of the greatest innovations is biodegradability of hot melt adhesives. These are already used in the packaging industry, and about to make an entry in the sector of hygiene products.

Choosing the best hygiene adhesive solution

The choice of adhesive for non woven materials in hygiene products basically comes down to two factors: the required bond strength between layers and effectiveness of elastic bonding. The latter is measured by elastic creep tests and the former by peel strength tests. The poor choice of adhesive can lead to for instance leakages and skin irritation. To avoid any inconvenience, contact us and let our experts find the best hygiene adhesive solutions that meet the requirements of your product needs.

Technologies that make up nonwoven construction adhesives

Traditionally, nonwoven construction adhesive systems can be based on two technologies which are waterborne systems and hot melt adhesives. The former have the advantage of being free of all harmful substances. They also have minimum risk to cause skin irritation. The downside is that water based adhesives tend to need a rather long time to dry.

However, the most reliable and comfortable hygiene products such as diapers, incontinence products, medical wound care products and feminine hygiene pads and shields currently use thermoplastic hot melt systems. These are plastic like 100% solid adhesives which take a liquid form when heated, hence the name hot melt. In general, hot melt adhesives for nonwoven materials allow for high production efficiency, low costs and extreme product reliability.

Advantages of the right adhesive for nonwoven materials

Once the nonwoven construction adhesive is carefully chosen, it can have a great impact on the quality and reliability of the finished products. The adhesive makes sure the nonwoven material remains elastic, seams are flexible and absorption properties are not disturbed. Additionally, ever-improving adhesives allow for thinner products with increased comfort and softness. All in all, thanks to hygiene construction adhesives, diapers, pads and incontinence products:

- Stay in place

- Are easy to remove

- Allow for movement

- Are discreet and do not show

- Feel soft and are comfortable to wear

- Result in less waste

Find the best hygiene adhesive solutions

Are you starting a new project and looking for suitable adhesives for nonwoven materials? Or do you wish to challenge your current adhesive supplier and look for an alternative? Whatever the case, our experts are always happy to assist in finding the most suitable and sustainable nonwoven hygiene construction adhesive that meets the product-specific requirements and results in outstanding finished products. Hit the contact button below and get more information.

Skin protectant plays an important role in wound care

Skin protectant is a thin barrier or layer which can be applied to damaged skin or to skin which is at risk of damage. The protectant provides a protective layer on the skin and enhances the healing process as well as protects the wound. Most skin protectants can be used together with dressings.

In this article we focus on skin protectant systems and their uses in wound care and damage prevention.

About wound healing

Wound healing is a process where the damaged skin repairs itself. The process consists of four main phases being: blood clotting, inflammation, tissue growth and tissue remodelling. Not only is the healing process complex, but also fragile and vulnerable to infections and reinjuries. Therefore wound care and wound management play an important role in the healing process. Many products including adhesives dressings and skin protectants can be used to support the process.

When to use a skin protectant

A skin protectant is a spray or film barrier applied directly to damaged skin or skin likely to be injured if not protected. Skin protectants form a barrier between the skin and the external threats. It is impermeable to external fluids yet breathable. Skin protectants facilitate wound healing by creating an environment beneficial for the process: the wound can breath while at the same time moist healing conditions are retained.

Skin protectants are generally not suitable for deep wounds or second or third degree burns. However, they can be used in numerous other situations such as the following.

- Protection from medical adhesives: wound care often requires use of adhesives. Also those that are suitable for long term wear, usually up to 7 days. Some of these adhesives, especially acrylic-based, are known for higher risk of skin irritation. Skin protectants can be applied direct to skin, forming a sort of a primer for the adhesive in order to prevent irritation.

- Peristomal skin damage: skin protectant can be applied to problem stomas which could otherwise contribute to fast skin erosion. The protective barriers are suitable when the stoma is in a difficult location or has high output.

- Periwound skin damage: the skin around a wound (periwound skin) can become damaged especially when the wound produces large quantities of drainage, in other words is infected. The surrounding skin can be protected with an appropriate skin barrier which enhances the healing of the periwound skin. Note that most skin protectants cannot be applied directly to the wound.

- Pressure ulcer/ injury: this refers to localized damage to skin and underlying tissue usually occurring on bony prominence or as a consequence of a medical device. Here a skin protectant can protect from moisture, friction and shear.

For more information on different types of skin protectans for various purposes, contact us. We are happy to help you out.

Benefits of skin protectants

Most skin protectant systems are made of special elastomeric polymers. Some of them are based on cyanoacrylate, the same ingredient that gives super glue its properties. Next to superior but non-irritant adhesion to skin, the protectants have plenty of other benefits.

- Breathability: one of the most important criteria for wound healing is breathability. Therefore also skin protectants allow the wound or skin breath at all times.

- Prevent cross contamination: most skin protectants are placed through a single use applicator, which prevents cross contamination.

- Maintain moist healing environment: usually skin protectants that are meant for already damaged skin prevent drying and allow the skin remain moist.

- Bioactivity: the most important benefit of innovative skin protectants is their bioactivity which means that they do not need to be removed but rather dissolve by themselves.

Looking for a supplier of skin protectants?

Skin protectants are suitable for several wound healing and prevention activities. In case you are curious about how the barriers can ease the pain of your patients and speed up the healing process, contact us and let us connect you with the industry-leading suppliers of skin protectants.

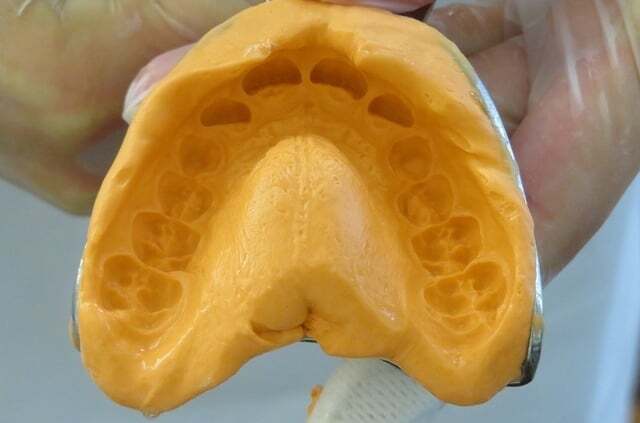

The many uses of dental wax

Dental wax makes an important material in dentistry as it provides benefits to making for example crowns, bridges, prostheses and dentures. The waxes are usually made of a combination of natural and synthetic wax and resins to guarantee the end product beneficial properties. Dental wax is mainly used in three situations:

- Making molds that give the shape to to the final crowns and bridges;

- Determining the required shape of crowns, dentures and prostheses;.

- Making models that can be fitted and easily altered when needed.

The 3 types – Dental pattern, processing and impression wax

Dental wax is generally a thermoplastic system which appears in a solid form in room temperature. When the temperature rises, the wax takes a liquid phase. Waxes do not have an exact melting point, but they rather have a melting range.

Even though the waxes behave in a similar way in different temperatures, there are numerous different products for the different purposes and situations we described in the beginning. The table below shows the three types dental wax can be divided into as well as more specific products that fall under each group of waxes.

| Type of dental wax | Products |

| Pattern wax | Inlay wax Modeling wax Milling wax Base plates Wax rim |

| Processing wax | Sticky wax Utility wax Boxing and beading wax Block-out wax |

| Impression wax | Corrective wax Bite registration wax |

1. Pattern wax

Pattern wax is the one that is used for making patterns and ensuring that they are the right ones for the patient. The use of dental pattern wax is close to the one of impression wax, however, here the single point is to capture and create the pattern for dental reconstruction. The products include inlay wax, milling wax, base plates and modeling wax.

- Inlay wax: used for fabrication of occlusal surfaces of dentures, crowns and bridges. The latter are first made in inlay wax and later converted into metal and ceramic casting.

- Milling wax: is used for milling and carving. These also exist as CAD/CAM milling waxes that support the computer aided processes.

- Base plates: traditionally pink or read dental wax sheets which are used for preparing patterns for prostheses. These are also used in making metal dentures, only then the color is usually green allowing the possible markings in the metal to remain visible.

- Modeling wax: dental modeling wax, also known as casting wax, is made for creating models of prostheses and bridges that can be fitted into the patient’s mouth and easily altered where needed. For CAD/CAM processes the wax is sometimes replaced by PMMA, a glass-like transparent plastic.

Need more information? If you would like to know more of any dental waxes or alternative products, please contact us. Our experts are determined to find the best possible solution for your needs.

2. Processing wax

Processing wax in dentistry refers to products used in making castings or during soldering. There are several types of processing waxes including boxing, sticky and utility waxes.

- Sticky wax: extremely sticky when melted and it adheres well to metals and ceramic materials. Sticky wax is used for aligning fractured parts of dentures, aligning fixed partial dentures prior to soldering and holding two fractured pieces together until they can be repaired.

- Boxing wax: a soft, pliable wax used for forming a wax box around an impression before it is poured with gypsum. Boxing wax comes in wax stripes which form a box with high enough edges to keep the liquid gypsum in place.

- Block-out wax: a special wax for blocking out cavities and rough surfaces in cast metal denture preparation.

3. Impression wax

The dental impression wax is used for determining the required shape of crowns, dentures and prostheses in order to guarantee a perfectly fitting product that causes no discomfort to the patient. Wax can be used in two cases: when a new product is made and when an existing one must be altered for whatever reason. The waxes used are bite registration and corrective waxes.

- Corrective wax: used to restore the selected area in edentulous patients mouths and reproduce the detail of mucous membrane.

- Bite registration wax: used to record the relationship of the upper and lower teeth of patients. Dental wax sheets and sticks are the most common means of doing so.

Note that impressions can also be made using silicone based dental putty.

Find the dental wax best for your process and the patient

Dental wax is a versatile product and picking the right one is not always a one-off decision. That is why our experts are here to help you! Click on the contact button below and share your needs with us to guarantee the best possible solution.

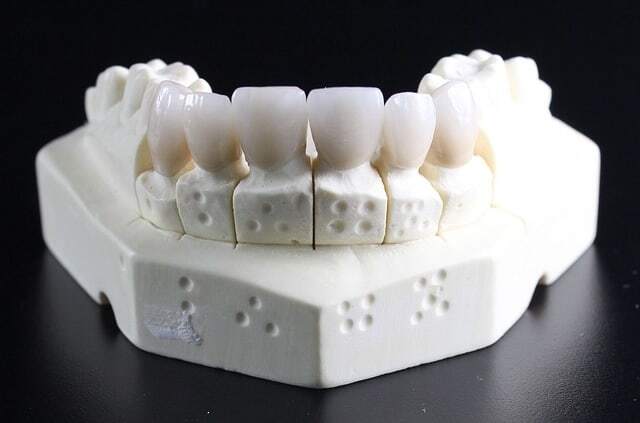

Silicone based dental putty as an impression material

Making dental impressions is a major part of dentistry. Therefore, there are different materials developed for the purpose suitable for the process of making crowns, bridges, braces and prosthesis. The most common dental molds and cast materials cure irreversibly, meaning that once they are in solid phase, they cannot be taken back to the liquid putty form.

In this article we focus on the dental silicone putty impression material types, as they are by far the most common dental impression materials.

The 2 types of dental silicone putty impression material

As impressions are made in different ways and for various purposes, there are two main types of dental putty and wax that can be used as impression putty. The types are classified by the way they cure: condensation cure and addition cure silicone dental putty impression material. Both of these silicone impression matterials cure irreversibly. Note that these putty material types are not compatible with each other.

1. Condensation cure silicone impression putty

Condensation cure silicone dental impression putty cures using tin salts as catalyst. This dental impression material is the most economical and easiest to use option and often chosen for when elevated temperatures are not involved. Condensation cure silicone shrinks slightly when curing.

This dental impressions material capture the tiniest details of the surface and are often biodegradable making them environmentally friendly.

2. Addition cure dental putty

The addition cure silicone putties are platinum catalyzed and they result in rubber like, more durable molds and casts as condensation silicones. They are also less sensitive to heat. These dental impression materials require careful mixing and application procedures. Due to the use of platinum as an ingredient and the longer processing times, addition cure silicone tends to be more expensive than condensation cure dental impression putty.

The most common type of addition cure putties is polyvinyl siloxane impression materials. These form durable and flexible dental molds and casts which resemble almost exactly the size before curing.

Would you like to know more about dental impression materials? Do not hesitate to contact us for assistance in finding the system you need.

What to consider when choosing the right dental putty

When choosing a dental impression material, it is of high importance to consider the application and manipulation phase, the patient (if applicable) and the purpose of the manipulated dental putty. Therefore, there is a list of factors to look at before the choice can be made.

- Viscosity

- Mixing time

- Working time

- Time in mouth

- Setting time

- Deformation under pressure

- Elastic recovery

- Total hardness

In need of a dental putty?

In case you are looking for a suitable dental impression putty, let us know. Our experts are happy to advise you making the right choice for your application, keeping in mind the patient, process and end result.